Fire Extinguisher - Safety

Breadcrumb

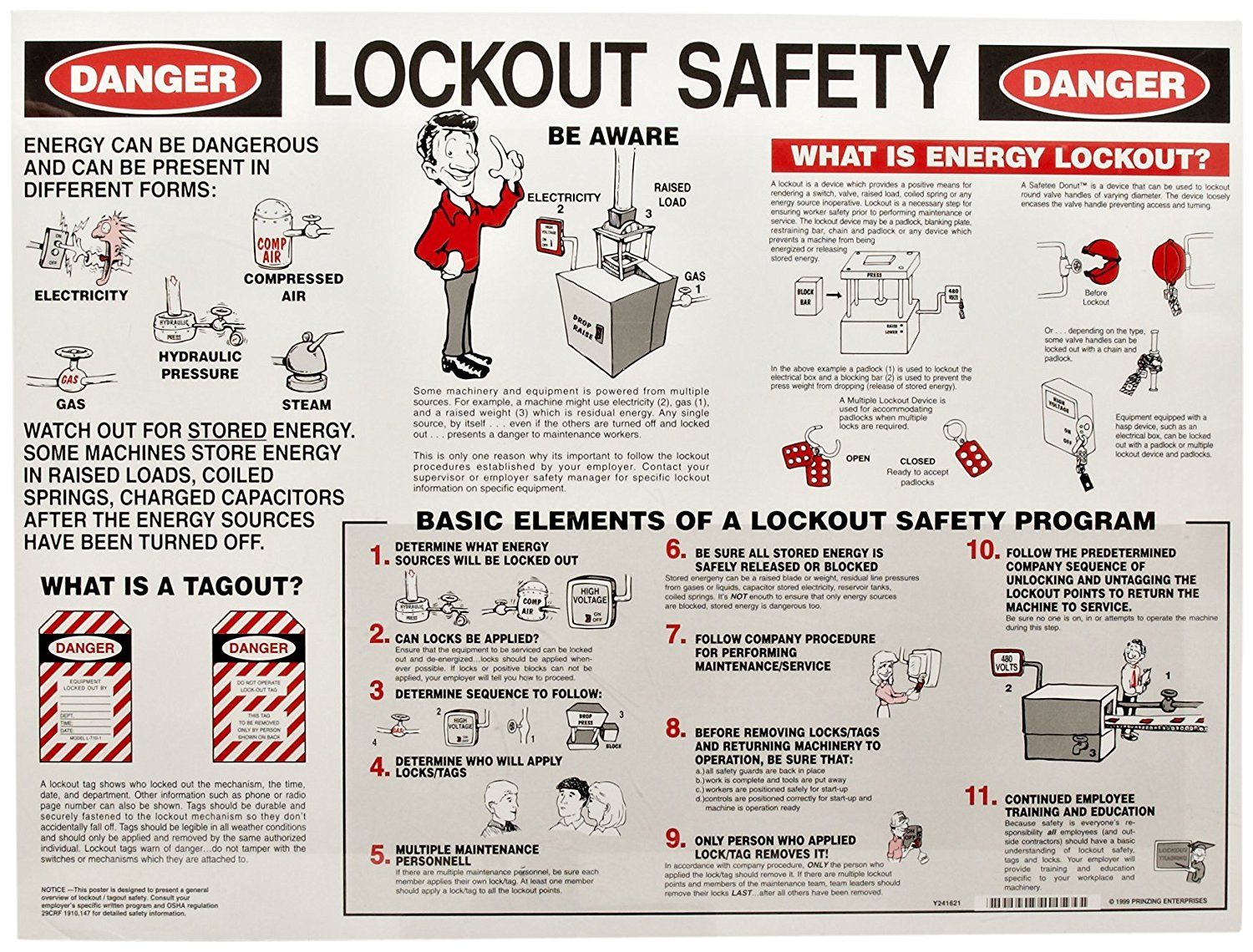

Lock Out / Tag Out Safety (LOTO)

LOTO Safety

The "Lockout/Tagout (LOTO)" procedure is a safety protocol used to prevent accidental or unintended startup of machinery and equipment during maintenance or servicing activities. The guidelines for electrical safety under LOTO include the following:

|

1

|

Authorized personnel: Only trained and authorized employees should perform LOTO procedures. | |

|

2

|

Locks and tags: Locks and tags should be used to physically prevent the activation of energy isolating devices. | |

|

3

|

Energy isolation: All sources of hazardous energy must be identified and isolated before maintenance or servicing activities are performed. | |

|

4

|

Verification of isolation: Before work begins, authorized employees must verify that the equipment is properly isolated and de-energized. | |

|

5

|

Written procedures: A written LOTO procedure should be in place and followed by all authorized personnel. | |

|

6

|

Group LOTO: In some cases, multiple workers may need to work on the same equipment. In these cases, a "group LOTO" procedure should be established to ensure the safety of all workers. | |

|

7

|

Regular review: The LOTO procedure should be reviewed regularly to ensure its effectiveness and to identify areas for improvement |

LOTTO / Tagout Periodic Inspection Form

References:

NPSINST 6055.1 NPS Hazardous Energy Control Program

29 CFR 1910.147, The Control of Hazardous Energy (lockout/tagout)

OPNAVINST 5100.23 Chapter 24, The Control of Hazardous Energy

FE types

The Types of Fire Extinguishers

A

Class A extinguishers are for use on fires that contain ordinary combustibles such as paper, wood, cloth plastics, etc.

B

Class B extinguishers are for use on fires containing flammable liquids like oil, gasoline

C

Class C extinguishers are for fires involving electrical equipment such as tools or appliances.

D

Class D extinguishers are for use on combustible metals. This type of extinguisher is generally only found in factories that work with these particular metals.

Resources